|

| |

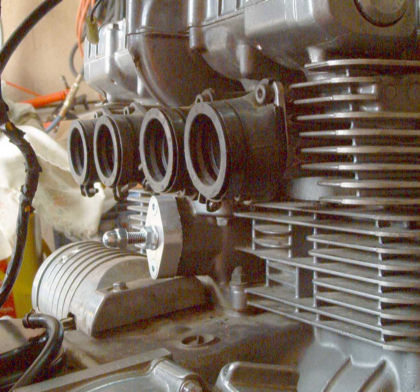

Zephyr Manual Cam Chain Tensioner

Installing the new manual cam chain tensioner:

- You will need a pair of 13mm wrenches, a 4mm hex key (allen

head) wrench or socket, ratchet, inch/lb torque wrench, gasket sealer, an

appropriate size socket/ratchet to turn over the engine.

- You may or may not have to remove the carburetors to do the

installation, I had them off so it was no problem. Adjustment can be made with

the carburetors on the bike.

- Remove the “automatic” tensioner body from the motor by

removing the two small bolts.

- Remove the Zephyr right side crank cover, easiest side to

work from.

- Back the adjustment bolt out a fair amount on the new

tensioner and remove the plastic sleeves from the mount bolts

- Put some Yamabond (Hondabond, Kawabond – whatever bond)

sealant or a similar goop on the tensioner gasket. I don’t know for sure, but

even grease may work fine.

- Install the tensioner in place threading in the supplied

countersunk bolts. On the Zephyr just install the tensioner either direction.

The adjuster bolt is centered so there is no difference.

- Torque the bolts to 72 in/lb (6 ft/lb or 8 N/m) if you

wish, I just used a 4 mm allen wrench and my “torque wrench arm”… if you know

what I mean.

- Turn the adjuster bolt in as far as possible by hand.

- Using the appropriate socket and ratchet on the bolt in the

end of the crank shaft,

A) From the right side, rotate the crank shaft clockwise slowly,

which will pull the cam chain taut on the drive side making the tensioner side

slack, while turning the tensioner adjustment screw by hand. DO NOT spin the

motor over with the starter, you risk jumping cam timing or possible valve

damage due to excess chain slack.

B) Turn the motor over for a few revolutions while applying

pressure by hand, The tensioner bolt will turn in easily when taking up slack

in the chain, but will resist turning when either the chain is under tension

(turning the crank the wrong way) or when the slack has been taken up.

C) You should be able to tell when the slack is gone, the bolt

will no longer turn easily.

D) Back off 1/6 turn (one flat of the acorn nut).

E) Using one 13mm wrench snug the tensioner locking nut down tight

while holding the acorn nut with the other 13mm wrench.

F) Rotate the crank slowly over again to make sure valves are not

out of time and hitting the pistons.

- Start the engine and warm it up to operating temperature.

- With the engine running, listen for any chain noise.

A) Tighten the tensioner bolt back in slightly (about 1/8 turn or

less) until rattle is gone.

B) Tighten the locking nut while holding the tensioner nut in

place with a wrench to keep it from turning.

This works without gimmicks and guesswork that can over

tighten the chains or let them flail around in the cases. Re-adjust every

several thousand miles or if you hear the rattle of cam chains again. I think

I’ve only done about 4 adjustments over the past 25,000 miles using the “sound”

method on the KLX. I didn’t need any change in adjustment on the Zephyr after

installation. The key point is what the tensioner does – it simply takes up

excess slack so the chain(s) don’t slap around and wear prematurely. There is no

preloading necessary.

Install the tensioner and take out the slack

by turning the crank while tightening the adjuster nut by hand.

Take off the right side crank shaft cover and rotate the crank shaft

clockwise using a 13 mm socket and ratchet or breaker bar.

|

|